Introduction

Laboratories require flooring that combines functionality, durability, and aesthetics. High-build epoxy coatings provide the ideal solution, offering superior performance while enhancing the visual appeal of your space. In this post, we’ll explore why epoxy floor coatings are the preferred choice for laboratory environments and the key benefits they offer, specifically with Garon’s TIGERSHIELD™ Epoxy Floor Coating. TIGERSHIELD™ is a colored epoxy floor coating that provides a thick protective layer to concrete floors.

Why Choose Epoxy for Laboratories?

Laboratories face unique challenges such as chemical spills, heavy equipment, and high foot traffic. Ordinary flooring materials often deteriorate under these conditions, leading to expensive repairs. Epoxy coatings solve these problems with exceptional durability, chemical resistance, and easy maintenance.

Durability and Longevity

Epoxy coatings are designed to withstand heavy wear and tear. Their robust structure ensures that laboratory floors stay intact and functional for years, even with constant use.

Chemical Resistance

Chemical spills are common in laboratory settings, but epoxy coatings are resistant to a wide range of chemicals. This prevents damage to the floor and reduces the risk of contamination.

Aesthetic Appeal

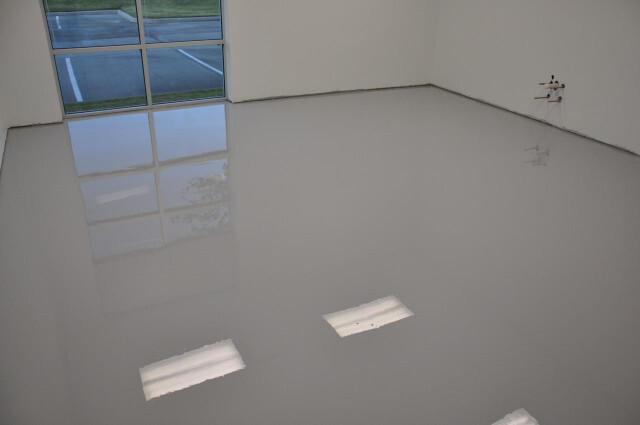

Epoxy coatings not only improve durability but also enhance the look of laboratory floors. With a sleek, glossy finish, epoxy transforms any floor into a seamless, professional surface.

Key Features of Tigershield™

TIGERSHIELD™ Epoxy Floor Coating is a standout product for laboratory floors. This two-component, 97% solids epoxy coating offers a high-build application, a glass-like finish, and excellent abrasion resistance, minimizing wear from heavy equipment or foot traffic. Stay tuned for our next post, where we’ll cover the step-by-step application process of high-build epoxy coatings, ensuring you achieve the best results for your laboratory.

Not sure which repair products are right for you?

Contact our team today.