Understanding the Impact of Temperature Extremes on Concrete Floors

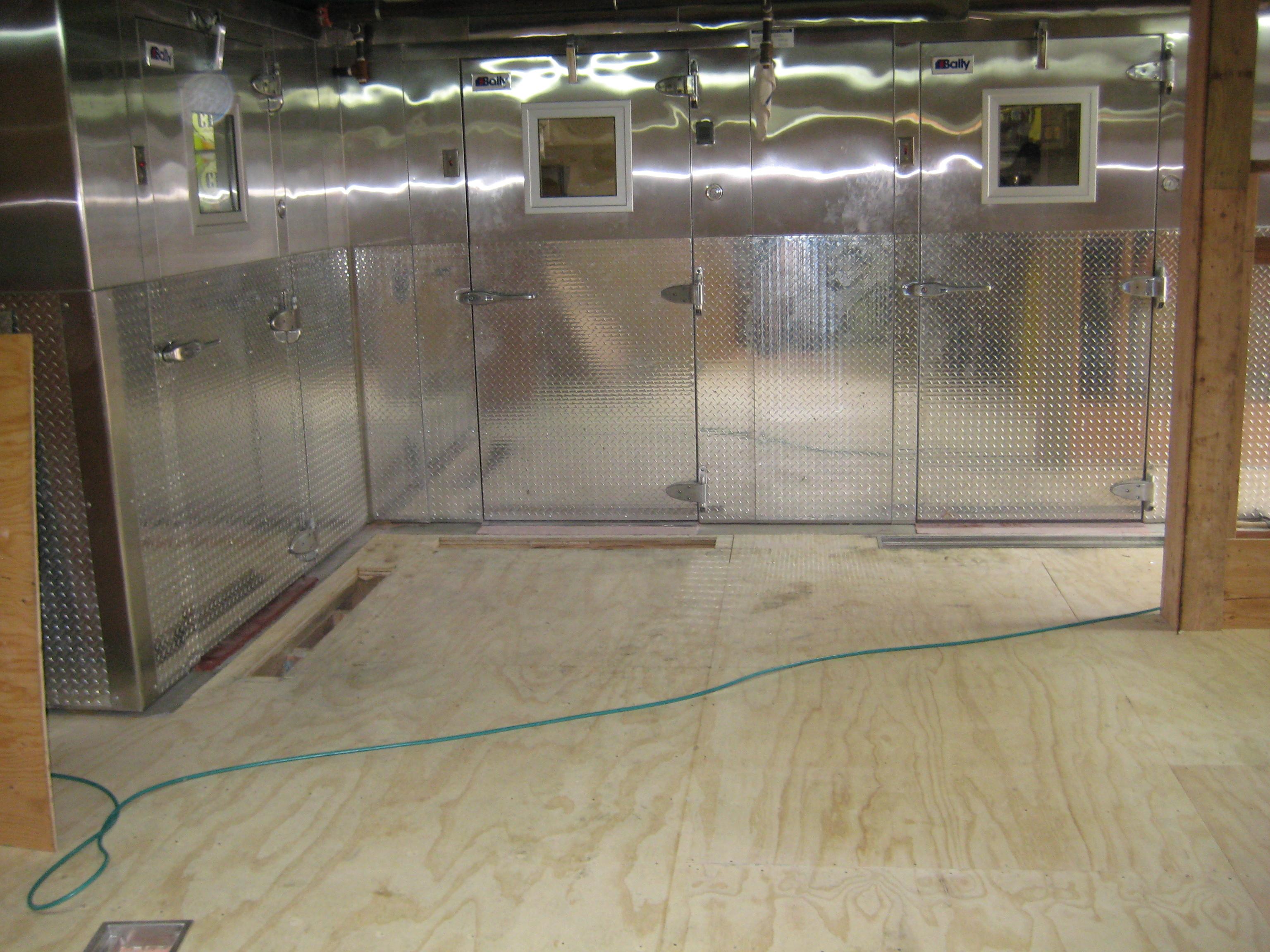

Concrete floors in food manufacturing settings are subject to various challenges, particularly from temperature fluctuations. These extremes can lead to significant issues such as cracking, surface degradation, and reduced durability. To mitigate these effects, it's essential to choose the right materials and application methods.

Step 1: Selecting the Appropriate Resurfacer

For environments exposed to frequent temperature changes, such as walk-in freezers or ovens, using a high-performance resurfacer is crucial. MORTARTHANE™ HF, a trowel-applied urethane cement floor resurfacer, is designed to withstand thermal cycling without compromising its integrity. This product ensures a durable, slip-resistant surface that can handle both hot and cold conditions effectively.

Step 2: Application Process

Begin by thoroughly cleaning the concrete surface to remove any contaminants. Once prepared, apply MORTARTHANE™ HF according to the manufacturer's guidelines. Its formulation allows for easy application and quick curing, providing a robust layer that protects the underlying concrete from thermal stress.

Step 3: Long-Term Maintenance

After application, regular inspections are necessary to identify any signs of wear or damage. Promptly addressing issues ensures the longevity of the floor and maintains its protective qualities. Additionally, periodic resealing may be required to enhance the floor's resistance to environmental factors.

Extending The Lifetime of Your Freezer Floors

By understanding the challenges posed by temperature extremes and selecting appropriate materials like MORTARTHANE™ HF, you can significantly extend the lifespan of your concrete floors, ensuring they remain functional and safe in demanding industrial environments.