How to Seal Mechanical Floors With TIGERSKIN™

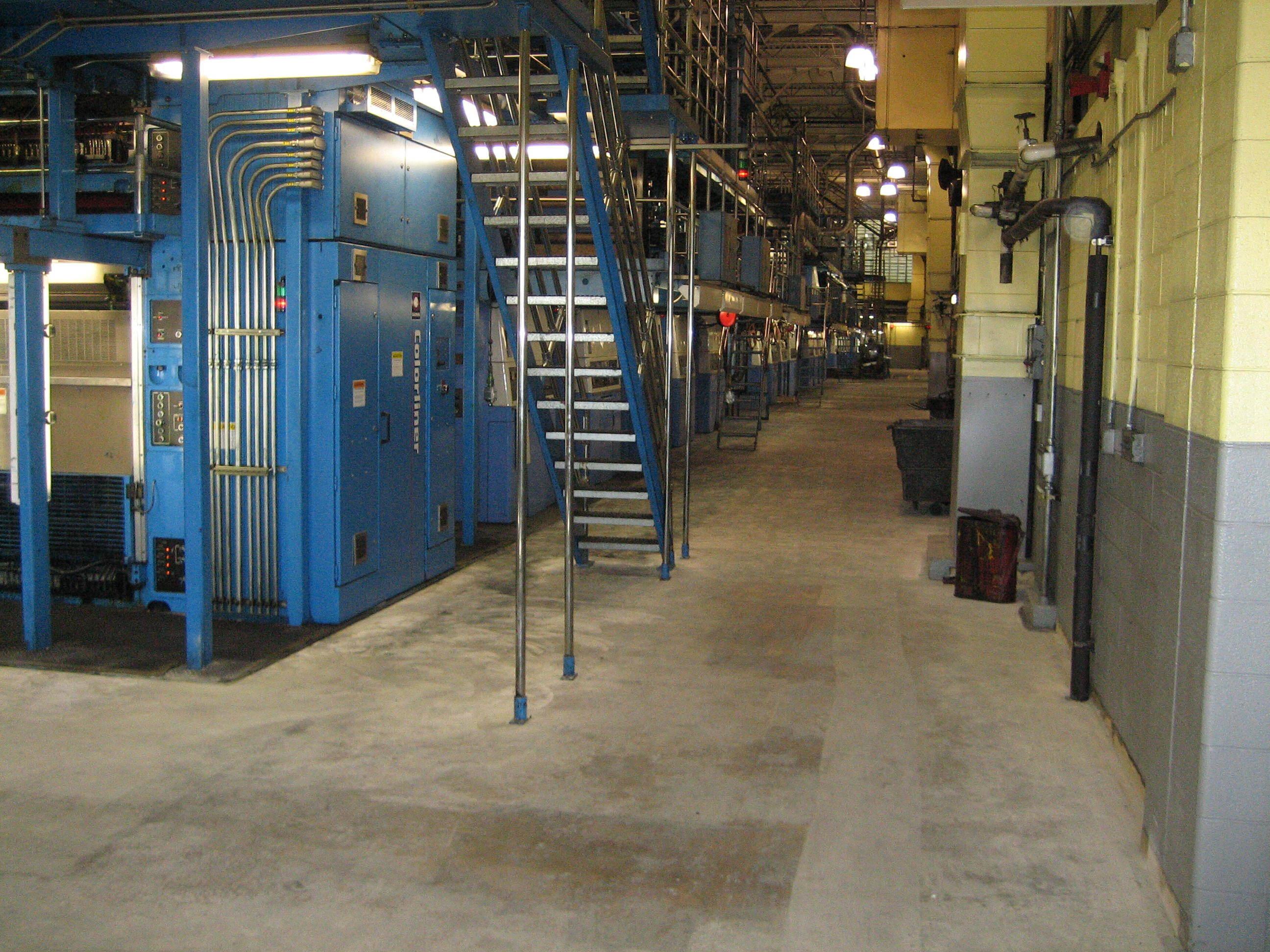

Sealing mechanical floors requires more than just durability, it demands a surface that can resist chemicals, impact, and daily wear. TIGERSKIN™ offers a reliable solution designed for heavy-duty environments like mechanical rooms, boiler rooms, and utility spaces.

Why Mechanical Floors Need Protection

Mechanical areas are subject to constant stress from equipment vibrations, fluid leaks, and temperature changes. Unsealed concrete can crack, stain, and absorb chemicals, leading to costly repairs. A proper floor sealer like TIGERSKIN™ creates a protective barrier that extends the life of your floor.

Step-by-Step Guide to Applying TIGERSKIN™

- Prep the Surface

Clean the floor thoroughly, removing grease, dust, and any loose material. For best adhesion, use mechanical abrasion such as shot blasting or diamond grinding. - Repair Any Damage

Patch cracks or holes with a compatible repair mortar. Let it cure before applying the coating. - Prime (If Needed)

While Tigerskin™ is self-priming in many cases, extremely porous floors may benefit from a primer layer to ensure even coverage. - Mix the Product

Follow the manufacturer’s instructions to mix TIGERSKIN™ thoroughly. It’s a 100% solids epoxy, so timing and consistency matter. - Apply the Coating

Use a roller or squeegee to apply an even layer across the floor. Focus on uniform thickness, especially around drains and high-traffic areas. - Allow to Cure

Let TIGERSKIN™ cure according to the guidelines. Mechanical rooms can typically be back in service within 24–48 hours.

Built to Last, Ready for Action

TIGERSKIN™ doesn’t just protect, it transforms. With its chemical resistance and industrial-grade toughness, it’s a smart investment for any mechanical floor that faces heavy use. When performance matters, seal it right the first time.