Heavy-Duty Epoxy Mortars for Industrial and Commercial Space

Introduction

Built to outperform traditional mortars, epoxy mortars for concrete offer a powerful combination of strength and protection. Epoxy mortar material is made with a combination of epoxy resin, hardeners, and mineral fillers that create an extremely durable bonding system.

Epoxy mortars are designed to restore, patch, and protect damaged concrete where traditional cement mortars fail. Because of its superior adhesion, compressive strength, and resistance to impact and chemicals, epoxy mortar is trusted for industrial flooring, structural repair, and environments with heavy traffic or harsh exposure.

What is an Epoxy Mortar?

An epoxy mortar is a heavy-duty concrete repair solution that delivers superior strength, chemical resistance, and long-lasting durability for industrial floors, joints, and high-traffic areas.

In high-traffic environments like warehouses, factories, and food processing facilities, uneven or damaged concrete floors increase the risk of accidents, injuries, and costly downtime. Epoxy mortars provide a fast, durable solution for concrete floor repair, delivering a seamless, level, and chemical-resistant surface that keeps operations safe, efficient, and compliant.

Industries That Rely on Epoxy Mortars

- Industrial Flooring Repairs – Fixing spalled joints, eroded slabs, and damaged warehouse floors with high-strength, impact-resistant epoxy mortar.

- Chemical Processing Plants – Flooring and trench repairs where acid-resistant epoxy mortars are essential to withstand corrosive chemicals and high temperatures.

- Food & Beverage Industry – USDA/FDA-approved epoxy mortars used in dairies, breweries, commercial kitchens, and bottling plants for hygienic, non-porous surfaces.

- Marine & Water Facilities – Repairing dams, piers, tunnels, wastewater plants, and containment areas where moisture resistance and structural integrity are critical.

- Parking Structures & Garages – Durable against vehicle traffic, salt, and de-icing chemicals, providing long-term protection for concrete decks and ramps.

- Educational & Institutional Facilities – Long-lasting, low-maintenance epoxy flooring for schools, universities, and public buildings with high foot traffic.

- Pharmaceutical & Healthcare Facilities – Seamless, sterile surfaces ideal for clean rooms, labs, and hospitals where contamination control is vital.

- Manufacturing Plants – Heavy-duty flooring and equipment base repairs that resist abrasion, vibration, and chemical spills.

- Cold Storage & Freezers – Epoxy mortars that cure in low temperatures, used for repairing floors in refrigerated environments.

- Retail & Commercial Spaces – Decorative epoxy mortar systems that combine durability with aesthetic appeal for showrooms, malls, and storefronts.

How to Apply Epoxy Mortars

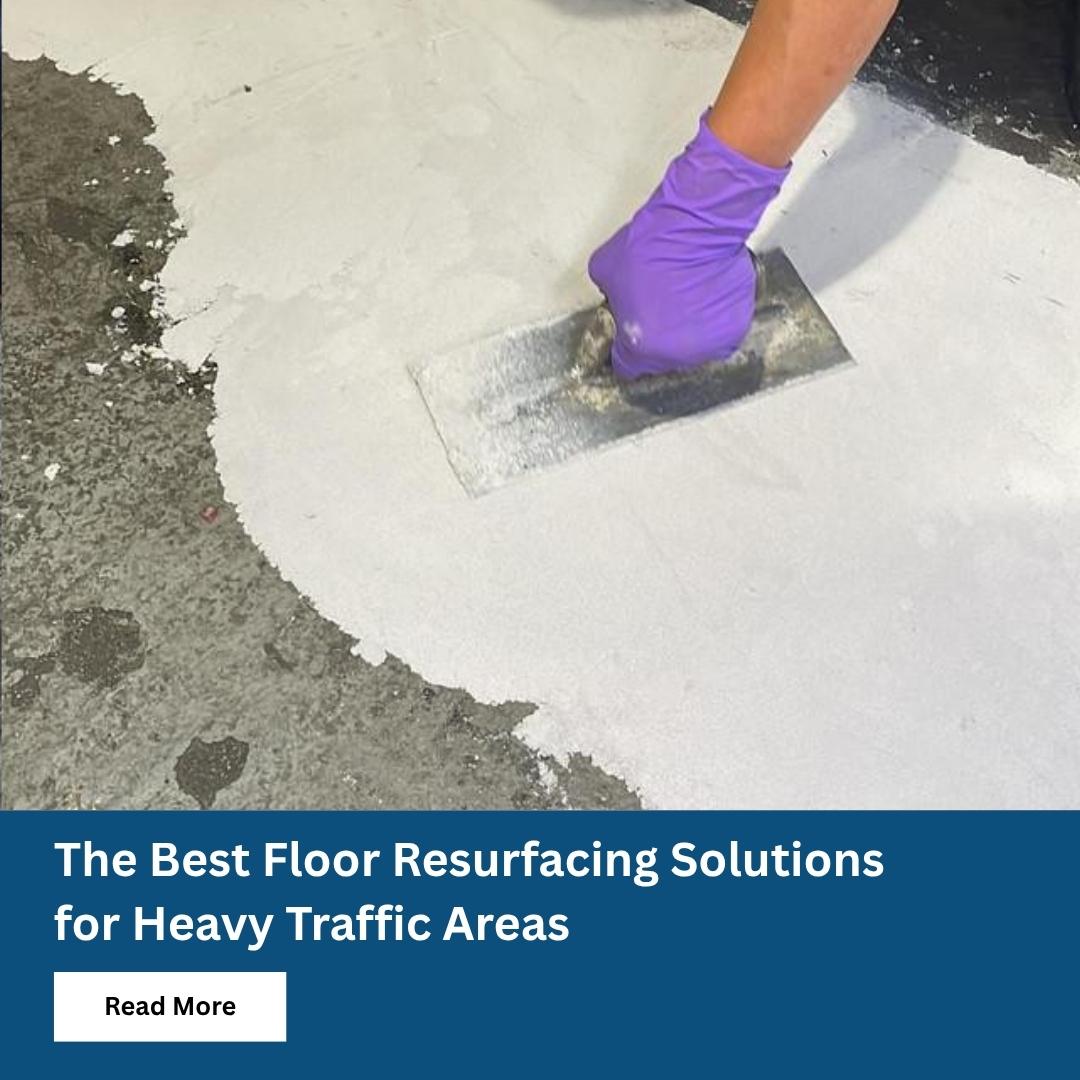

Applying epoxy mortar is quick and straightforward, making it a reliable solution for concrete repair and floor patching in industrial and commercial spaces. Follow these simple steps:

- Mix the Epoxy Mortar

Combine the epoxy resin and hardener with the aggregate as directed. Mix thoroughly until you achieve a smooth, uniform consistency. Proper mixing ensures the strength, adhesion, and durability of the repair. - Pour the Mortar

Once mixed, pour the epoxy mortar directly into cracks, holes, or damaged areas of concrete. For larger repairs, spread the material evenly across the surface. Epoxy mortar’s self-leveling and fast-curing properties help reduce downtime. - Spread and Smooth

Use a trowel or spreader to smooth the mortar over the repair area, making it level with the surrounding floor. This step creates a seamless, durable surface that can handle heavy traffic, machinery, and chemical exposure once cured.

Garon's Epoxy Mortar Concrete Repair Solutions

|

TREFLITE™ Epoxy Mortar Patch/Resurfacer

|

|

ARCTIC FREEZITE™ Epoxy Mortar Patch/Resurfacer

|

FAQS for Epoxy Mortars

FAQ 1: What is an epoxy mortar vs. a cement mortar?

Epoxy mortar is a high-strength, chemical-resistant bonding material made from epoxy resin and sand, ideal for industrial and harsh environments. Cement mortar, composed of cement, sand, and water, is more economical and widely used in general construction but lacks the durability and resistance of epoxy mortar.

FAQ 2: What is an epoxy mortar used for?

Epoxy mortar is commonly used for industrial flooring, chemical-resistant surfaces, repairing concrete structures, and bonding tiles or stones in environments exposed to heavy loads, moisture, or corrosive substances. Its durability and resistance to chemicals make it ideal for factories, commercial kitchens, laboratories, and wastewater treatment plants.

FAQ 3: Can an epoxy mortar be used on tile?

Yes, epoxy mortar can be used on tile.

Not sure which repair products are right for you? Contact our team today.