Restoring Durability and Safety: Industrial Epoxy Flooring for Auto Parts Manufacturing

The Problem:

A 45-year-old auto parts manufacturing facility faced significant challenges with its aging concrete floors. The existing coatings had deteriorated, leading to peeling and delamination, while cracks and joints compromised the floor's integrity. With continuous 24/7 operations, the facility required a flooring solution that would withstand heavy forklift traffic and maintain safety standards.

Step-by-Step Flooring Solution: How to Transform Concrete Floors

Surface Preparation: The existing floor coatings were removed, and the concrete surface was thoroughly cleaned.

Crack and Joint Repair: Deep voids and cracks were filled using GARON POXYPASTE™ and JOINT GUARD™ to restore the floor's structural integrity.

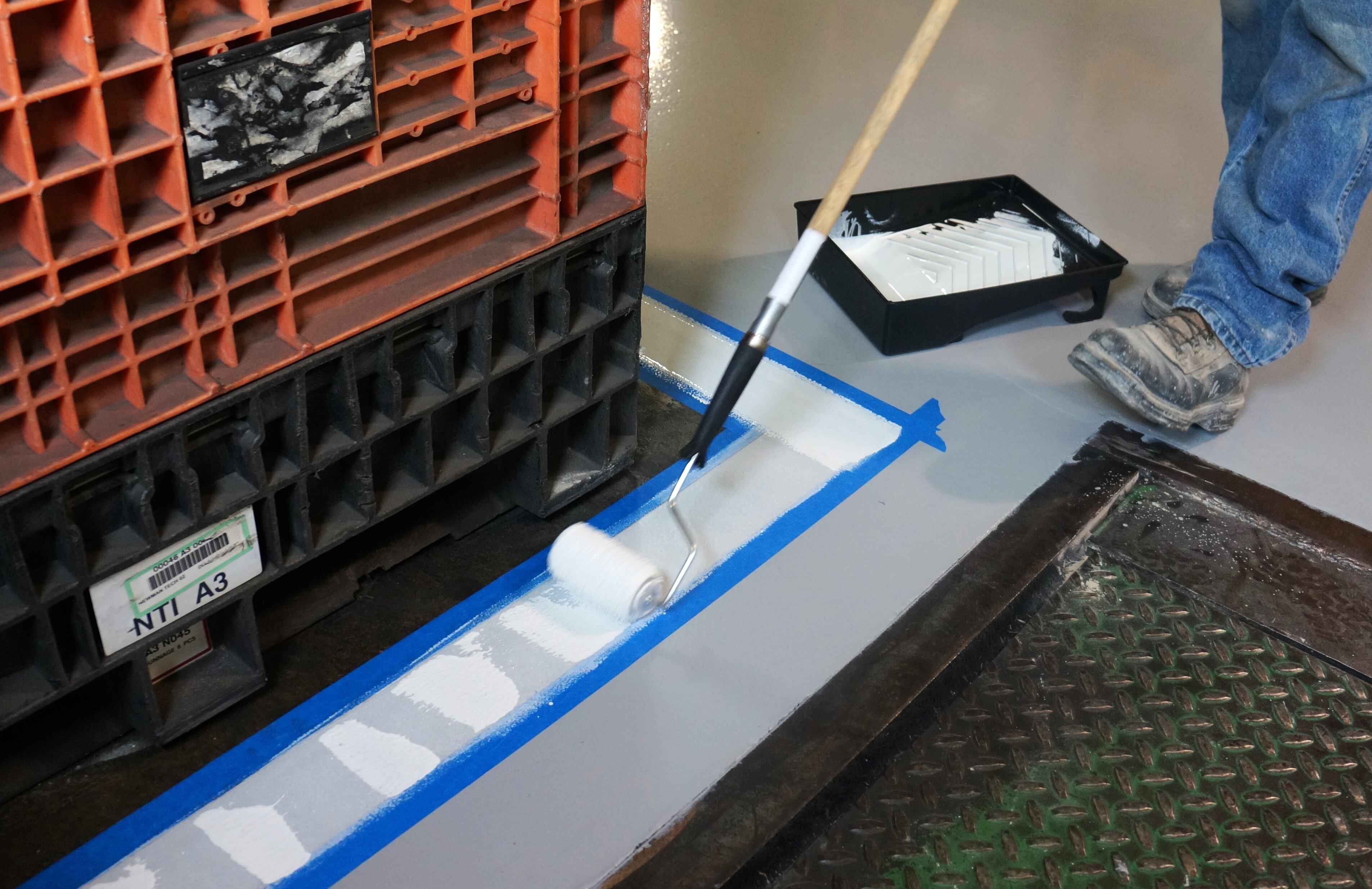

Epoxy Coating Application: Two coats of GARON GUARD™ 100% solids epoxy was applied, achieving a nominal thickness of 30 mils, providing a durable and seamless surface. To apply the epoxy floor paint, just mix, pour and roll!

Line Striping: TIGERSTRIPE™ epoxy line striping was used to delineate forklift lanes, enhancing safety and operational efficiency.

Curing and Inspection: The floor was allowed to cure, and a final inspection ensured all specifications were met.

Outcome and Benefits

The project was completed within a 6-day timeframe, minimizing downtime and allowing the facility to resume full operations promptly. Each product comes in a pre-measured concrete floor repair kit. The new flooring system not only improved the floor's durability and safety but also enhanced the facility's overall appearance and functionality.

A Foundation Built to Last

This flooring upgrade exemplifies how strategic planning and quality materials can transform industrial spaces. By addressing both aesthetic and functional needs, the facility now operates on a floor that supports its demanding environment and contributes to long-term success.

Contact us today with any questions about which products to use for your concrete repair projects!